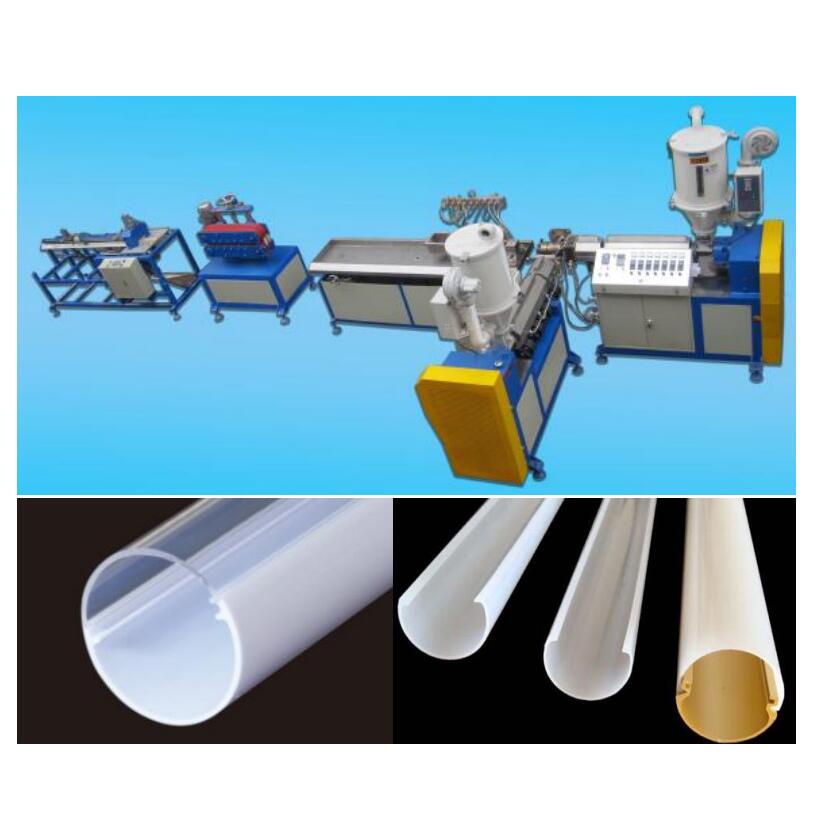

PC tube production machine

Introduction:

1. Usage & scope of application

The production line is mainly used to produce fluorescent tube, LED tube, PC tube, transparent twin-color tube, frosted tube and types of fluorescent tube include glossy, two-color, abrasive, sandblasted, photodiffusion and semi-cycle, etc.

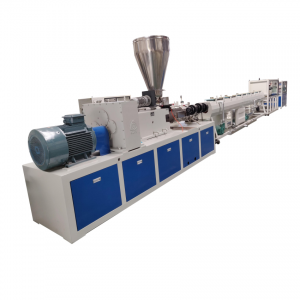

2. Machine composition & characteristics

Our profile production line has may advantages such as unique structure, high automation, easy to operate and continuous production stable and reliable, etc.

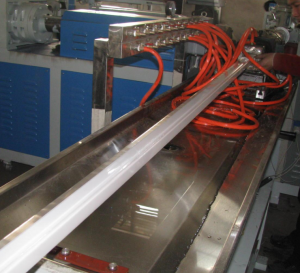

Production flow chart: raw material → specialized extruder → profile mould → vacuum setting table→ tractor → cutter → stacker

Main characteristics:

The extruder uses high efficient screw with frequency speed control to achieve stable start of low speed. The temperature errors can be controlled within ±1℃ by imported temperature meter. Different extruders are used according to different raw materials. The water collect basin for setting table is made by stainless steel with top quality vacuum pump. The tractor is controlled by inverter. It can lift manually or automatically. The cutter uses overseas blade to.

Main technical parameters of PC tube production machine:

| Max.Section of Products(mm): | 50X50 |

| Drawing speed(m/min): | 0.2-3 |

| Power(kw): | 20 |

| Capacity(kg/h): | 20 |

| Water consumption (m3/h): | 1 |

| Gas consumption(m3/h): | 0.15 |

| Appearance size(m): | 12000X1000X1900 |

| Weigh(kg): | 2000 |