PVC FASCIA AND BARGE BOARD production machinery

Features of the Machine:

1)Extruder screw and barrel from Zhoushan,with vacuum degassing system, can get rid of the waste gas from the raw material which can ensure good quality of final granules.

2) Gearbox: From Jiangyin gearbox company,very famous brand in China,with nice outline, stable running, low noise and long service time.

3) Heating system: adopting cast aluminum heaters with stainless steel plate covers, wind fan cooling system, ensuring good features of cooling and heating, precision temperature controlling.

4) Driving system: adopting Siemens motor, using ABB inverter which provide stable torque output and various speed.

5) Vacuum calibrating and cooling Table: the tabley is made by #304 stainless steel, good strength and performance,long life time.

6) Traction machines:Rubber block traction belt,traction speed is adjustable by ABB frequency inverter.

7) Cutting machine: saw blade cutting,low noise,quick cutting performance,with dust collection device.

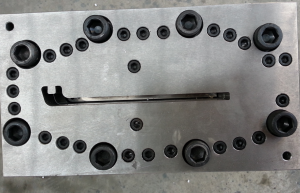

Main Machine Flow Chart

Screw Loader for Mixer---High Speed Mixing Unit---Screw Loader for Extruder---Conical twin screw extruder---Mold---Vacuum calibration machine---Traction Machine---Cutting Machine---Stacking Table

Main technical parameters of PVC FASCIA AND BARGE BOARD PRODUCTION MACHINE :

| Model | YF180 | YF240 | YF300 |

| Max. profile width (mm) | 180 | 240 | 300 |

| Total power of auxiliary machines (kw) | 18.7 | 27.5 | 33.1 |

| Cooling water volume (m3/h). | 5 | 7 | 7 |

| Compressed air (MPa) | 0.6 | 0.6 | 0.6 |